Glass partitions have become essential elements in contemporary office design, offering practical solutions for space division while maintaining visual openness. These transparent barriers create defined areas without the closed-in feeling of traditional walls, making them particularly valuable in urban environments where natural light is precious. Businesses increasingly recognize that glass partition systems can enhance productivity by reducing noise levels while keeping teams visually connected.

Selecting the right glass partition provider requires careful consideration of factors beyond basic installation services. Quality materials, engineering expertise, and reliable customer support all contribute to successful project outcomes. This guide examines seven companies that have established strong reputations in the glass partition industry through their technical capabilities and customer satisfaction records.

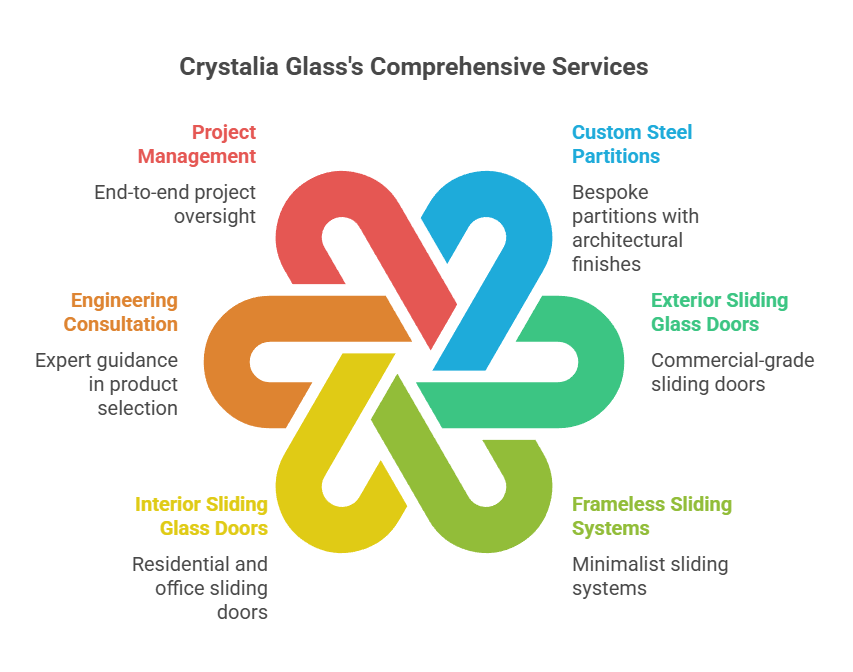

Crystalia Glass

Founded in 2017, Crystalia Glass specializes in European glazing systems and operates throughout a 400-mile service radius from their Brooklyn location. The company differentiates itself through bespoke steel partition systems that combine structural integrity with visual appeal.

Core Product Offerings

- Custom steel partitions with architectural-grade finishes

- Exterior sliding glass doors for commercial applications

- Frameless sliding systems with minimal visual profiles

- Interior sliding glass doors for residential and office use

Each installation receives attention from experienced engineers who guide clients through the selection process, ensuring that technical specifications align with project requirements. The company focuses on competitive pricing while maintaining quality standards, which appeals to both residential clients upgrading home offices and commercial property managers working within budget constraints.

Customer testimonials frequently mention the responsiveness of their installation teams and the durability of finished systems. What sets Crystalia apart is their emphasis on complete project management. From initial consultation through final installation, clients work with the same engineering team, which reduces communication gaps that often complicate construction projects. Their expertise in sliding glass wall systems makes them particularly suitable for applications requiring flexible space configurations.

ZONA Glass Wall Systems

ZONA produces glass wall systems in the United States and distributes them through a network across North America. Their engineering approach prioritizes consistency, allowing architects to maintain uniform aesthetics across different applications within the same building.

Technical Specifications

| Feature | Specification | Benefit |

|---|---|---|

| Frame Thickness | 50% above industry standard | Enhanced structural stability |

| Profile Height | 1½ inches | Consistent alignment across configurations |

| Stress Point Design | Integrated steel bracing | Prevents frame deflection over time |

| Manufacturing | US-based with recycled content | Sustainability and local labor support |

The company manufactures frames that are 50% thicker than industry standards and incorporates steel bracing at stress points. This construction method addresses a common limitation in glass partition systems, where frame deflection can compromise both appearance and acoustic performance over time.

ZONA’s technical support extends beyond installation. Their engineering team assists with code compliance issues, acoustic requirements, and multifunction space planning. Projects requiring high sound transmission class (STC) ratings benefit from ZONA’s experience with acoustic glass systems. This approach appeals to organizations pursuing sustainability certifications or implementing environmental responsibility programs.

Metro Wall

Metro Wall serves commercial clients requiring interior glass solutions that balance transparency with privacy. Their systems accommodate various glass types, from clear panels that maximize light transmission to frosted options that obscure visibility while maintaining brightness.

The company structures their offerings around modular components, which simplifies future reconfigurations. This design philosophy proves valuable for businesses anticipating growth or reorganization. Maintenance requirements remain minimal due to the use of corrosion-resistant hardware and tempered safety glass.

Service Advantages

- Detailed site surveys that identify complications before fabrication

- Warranty coverage for both materials and installation workmanship

- Accessible technical support after project completion

- Guidance on cleaning procedures and expansion possibilities

Metro Wall’s installation process includes detailed site surveys that identify potential complications before fabrication begins. This preparation reduces on-site modifications and helps projects stay on schedule. Technical support personnel remain accessible after project completion to address questions, which distinguishes them from providers who limit client contact to the pre-installation phase.

View

View brings a technology-driven approach to architectural glass products. Their systems incorporate electrochromic glass that adjusts tint levels automatically in response to sunlight intensity. This dynamic functionality reduces cooling costs while preventing glare issues that can affect computer screen visibility.

The company targets commercial buildings where energy efficiency directly impacts operating expenses. Property managers appreciate the ability to control entire glass wall systems through centralized software, eliminating the need for window treatments and the associated maintenance requirements.

Key System Features

- Automatic tint adjustment based on sunlight intensity

- Integration with building automation platforms

- Centralized control through proprietary software

- Synchronization with HVAC and lighting systems

- Measurable energy consumption reductions

Installation requires coordination between electrical contractors and glazing specialists, which View facilitates through detailed technical documentation. Long-term performance data from existing installations demonstrates measurable reductions in energy consumption. These metrics help organizations calculate return on investment periods and justify premium pricing compared to static glass systems.

Modernco

Modernco specializes in operable glass partition systems suitable for spaces requiring occasional reconfiguration. Their moveable walls provide sound isolation when extended and store compactly when not needed. Conference facilities, hotels, and educational institutions frequently specify these systems for multipurpose rooms.

The company offers multiple operation methods, including manual track systems and motorized options with remote controls. Engineering teams help clients evaluate which approach best suits their usage patterns and budget parameters. Sound attenuation ratings reach levels appropriate for speech privacy and music venue applications.

Operation Options Comparison

| System Type | Best For | Typical Applications |

|---|---|---|

| Manual Track | Budget-conscious projects | Small conference rooms, classrooms |

| Motorized Standard | Frequent reconfiguration | Hotel ballrooms, community centers |

| Motorized Premium | Large installations | Convention centers, performance venues |

Installation precision determines long-term operational quality in operable systems. Modernco’s field crews verify floor levelness and structural support capacity before mounting track hardware. This thoroughness prevents binding issues and premature wear on moving components. Maintenance programs include periodic inspection of seals, track alignment, and operating mechanisms, which extends system lifespan significantly.

Kwik-Wall

Kwik-Wall manufactures portable partitions that serve temporary space division needs. Their systems deploy without permanent attachment to floors or ceilings, making them appropriate for rental spaces and facilities where conventional construction isn’t permitted.

Healthcare providers use these partitions for intake screening areas, while event venues employ them to create breakout spaces. The product line includes options with integrated doors, pass-through windows, and electrical channels for power distribution.

Portable System Benefits

- No permanent installation required

- Assembly with basic tools by facility staff

- Disassembly for storage or relocation

- Multiple site usage from single investment

- Transparent panels maintain supervision sightlines

Assembly requires basic tools and can be completed by facility staff without specialized glazing experience. Panels disassemble for storage or relocation to different sites. While not offering the acoustic performance of permanent installations, Kwik-Wall systems reduce conversational distraction in open environments.

Organizations operating in multiple locations value the portability aspect. A single investment in Kwik-Wall panels can serve various projects sequentially rather than requiring new materials for each temporary need. This flexibility offers economic advantages over both permanent construction and conventional temporary walls.

AGA

AGA provides architectural glass products through a distribution model that connects specifiers with appropriate manufacturers and installation contractors. Their technical representatives assist with product selection based on performance requirements, building codes, and aesthetic objectives.

The company maintains relationships with multiple glass partition manufacturers, which allows them to source specialized products for unique applications. Projects requiring fire-rated glass, bullet-resistant panels, or heritage building compatibility benefit from this broad supplier network.

Distribution Model Advantages

- Access to multiple manufacturer products

- Single point of contact for complex projects

- Coordination between fabricators and installers

- Logistics management for compressed schedules

- Warranty administration and service coordination

AGA’s value proposition centers on project coordination rather than direct manufacturing. They manage logistics between glass fabricators, hardware suppliers, and installation teams. This orchestration proves particularly useful for complex projects involving multiple building trades working on compressed schedules. Post-installation support includes warranty administration, and when issues arise, AGA acts as the single point of contact.

Making the Right Selection

Choosing among glass partition providers depends primarily on project requirements rather than broad quality comparisons. The following table helps identify which provider types match common project needs.

Provider Selection Guide

| Project Requirement | Recommended Provider Type | Example Companies |

|---|---|---|

| Custom systems | Specialty fabricators | Crystalia Glass |

| Structural superiority | US manufacturers | ZONA |

| Energy efficiency focus | Technology integrators | View |

| Reconfigurable spaces | Operable system specialists | Modernco |

| Temporary installations | Portable system providers | Kwik-Wall |

| Complex specifications | Distribution coordinators | AGA |

Budget considerations extend beyond initial installation costs. Systems requiring minimal maintenance and offering long warranties can deliver better lifetime value despite higher upfront expenses. Conversely, temporary installations merit more economical solutions that match their limited duration.

Geographic location affects both installation costs and service availability. Local providers often respond faster to warranty claims and can conduct site visits more economically. However, specialized products may justify working with distant suppliers if local options lack required capabilities.

Acoustic performance specifications deserve particular attention in environments where speech privacy matters. Testing data should confirm STC ratings rather than relying on general claims. Building codes may mandate specific performance levels for healthcare facilities, financial institutions, and legal offices.

Installation Considerations

Successful glass partition projects require thorough planning before installation begins. Structural engineers should verify that floor systems can support concentrated loads at partition base points. Older buildings may need reinforcement to accommodate modern glass wall systems safely.

Pre-Installation Checklist

- Structural capacity verification by licensed engineer

- Access logistics planning for material delivery

- Coordination schedule with electrical and HVAC trades

- Staging area identification for assembly work

- Testing protocol establishment for final acceptance

Access logistics deserve early attention, particularly for high-rise installations or facilities with restricted delivery hours. Large glass panels require careful handling and may necessitate specialized equipment for vertical transport. Installation crews need adequate space for staging materials and assembling components.

Coordination with other trades prevents conflicts that can delay project completion. Electrical contractors must rough in power for systems requiring motorized operation or electrochromic functionality. HVAC engineers should review how glass partitions affect air distribution patterns and thermal zones. Testing protocols should be established before final acceptance, including verifying door operation, checking seal integrity, and confirming acoustic performance where specified.

Maintenance and Longevity

Glass partition systems require periodic maintenance to preserve appearance and functionality. The following maintenance schedule applies to most commercial installations.

Recommended Maintenance Schedule

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Glass cleaning | Weekly to monthly | Use manufacturer-approved cleaners only |

| Hardware lubrication | Quarterly | Focus on hinges, tracks, and locks |

| Seal inspection | Annually | Replace if compression or gaps detected |

| Acoustic testing | Every 3-5 years | Required for critical privacy areas |

| Hardware adjustment | As needed | Address squeaks or resistance immediately |

Cleaning protocols vary based on glass type and coating treatments. Abrasive cleaners can damage specialized surfaces, so manufacturers’ recommendations should be followed carefully. Hardware components need occasional lubrication and adjustment, as door hinges, track systems, and locking mechanisms experience wear from regular use.

Seal replacement represents the most common long-term maintenance requirement for acoustic systems. Gaskets compress over time, reducing their sound-blocking effectiveness. Scheduling seal replacement during regular facility maintenance cycles proves more economical than emergency interventions. Glass panels themselves rarely require replacement unless damaged by impact.

Final Thoughts

The glass partition industry offers diverse solutions tailored to specific commercial and residential needs. Companies like Crystalia Glass deliver custom European systems with personal service, while ZONA emphasizes American manufacturing and structural superiority. Technology-focused providers like View address energy efficiency concerns through smart glass integration.

Project success depends on matching provider capabilities with actual requirements. Temporary installations don’t require the engineering sophistication needed for permanent acoustic barriers. Similarly, simple space division doesn’t justify the expense of electrochromic systems designed for dynamic sun control.

Working with experienced providers yields benefits beyond quality products. Their insights regarding code compliance, maintenance planning, and future flexibility can prevent costly mistakes. Taking time to evaluate options thoroughly produces better outcomes than rushing decisions based solely on price comparisons.